Technical Support/Technical Support

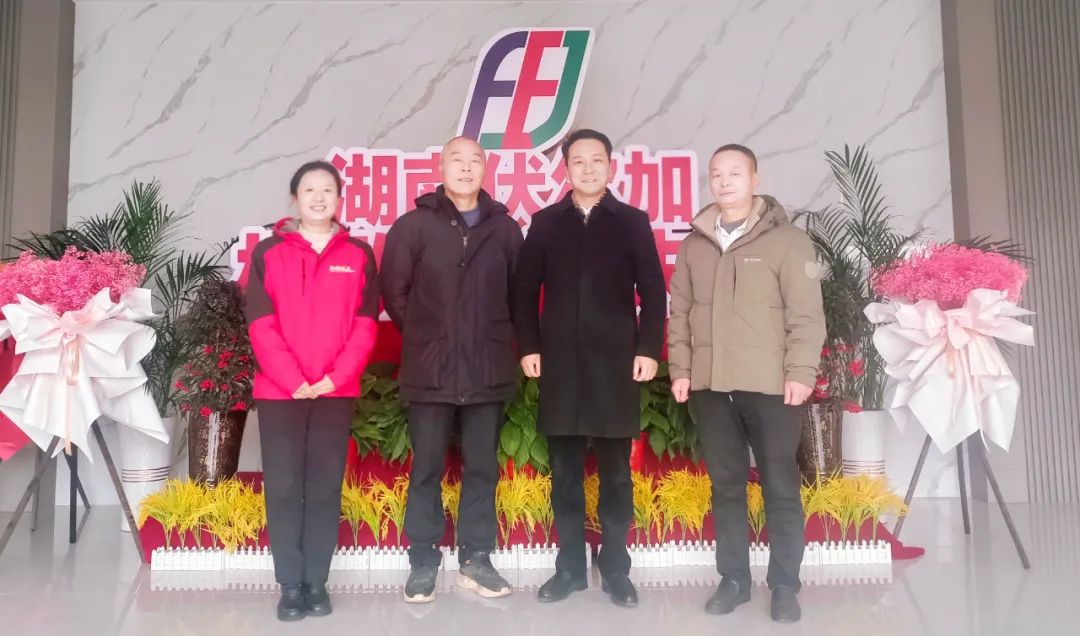

Warmly welcome Xiangtan County Mayor Wang Li and Chairman Liu Xianlin of Baiyi Garden Enterprise to visit our company

Release time:

2024-01-27

Source:

On January 25, 2024, Wang Li, head of Xiangtan County, and Liu Xianlin, chairman of Baiyi Garden Enterprises, visited our company for a field visit, and the person in charge of our company actively received them. Wang Yuan, deputy general manager, and Zhao Lihong, deputy general manager of the manufacturing center, respectively introduced in detail the scale of the enterprise, the main products and the development of the rotary power drive device industry.

Express today

Express today

On January 25, 2024, Wang Li, head of Xiangtan County, and Liu Xianlin, chairman of Baiyi Garden Enterprises, visited our company for a field visit, and the person in charge of our company actively received them. Wang Yuan, deputy general manager, and Zhao Lihong, deputy general manager of the manufacturing center, respectively introduced in detail the scale of the enterprise, the main products and the development of the rotary power drive device industry.

Express today

Deputy general manager Wang Yuan detailed Volga rotary digging power head products.

Express today

Zhao Lihong, deputy general manager of the manufacturing center, introduced in detail the production process and technology of Volga rotary digging power head.

Express today

Wang Li, head of Xiangtan County, visited our company for the purpose of in-depth understanding of Volga Company, highly recognized our products and development, and placed the expectation of maintaining the spirit of innovation.

Thanks to the government's attention and support for the development of our company, our company will not forget its original intention, "start from the new, go to the heart", and strive to become bigger and stronger, and become a high-quality and warm enterprise. To contribute to the economic development of Xiangtan County.

First from left: Ms. Wang Yuan, Deputy General Manager of Volga Second from left: Mr. Liu Xianlin, Chairman of Baiyi Garden Enterprise

Right one: Mr. Zhao Lihong, Deputy General Manager of Volga Right two: Mr. Wang Li, Magistrate of Xiangtan County

Related News

Maintenance and Maintenance of Power Head of Rotary Drilling Rig

2018-04-24

There are many models of crawler rotary drilling rig manufacturers, how should we choose?

2018-03-27

Decryption of Power Head Structure of Rotary Drilling Rig

2018-03-20

How to solve the oil leakage of power head of rotary drilling rig?

2017-12-23